Milan Mládek

I was born in Trutnov in 1930. My family belonged to prominent Czech linen manufacturers. We owned a spinning mill in Studenec, which was part of Sudetenland, annexed by Nazi Germany in 1938. The factory was confiscated by the Germans. My father Josef regained control over the business after the war, but Czechoslovak industries were then nationalized and the Communist takeover in 1948 meant the loss of all hope. Father was even imprisoned for a short while. I was a grammar school student back then. After he was released, with no charge, he decided we had to leave the country as soon as possible. I still remember how my parents and myself had to walk in silence over the border, carrying everything we could. We found ourselves in Germany and then some friends helped us to get to Belgium where we stayed without any idea what our future will be.

Zdeněk fled to London just before the German occupation and confiscation

My older brother Zdeněk has already been abroad. When it still was possible to travel abroad legally, my father sent Zdeněk to study languages and learn about textiles. It happened to be Belfast, sort of a Mecca of the linen industry at that time, where he settled. It is important to note that our family’s history has been linked with the Sochor family. At the beginning of the 20th century, Mr. Josef Sochor founded a textile printing factory in Dvůr Králové. It soon became a world leader in the introduction of the most modern printing technologies, owned a number of patents for screen printing and employed over 1,500 people. His son Zdeněk fled to London just before the German occupation and confiscation of the company’s assets. He received permission and a grant from the British Ministry of Commerce to print dress material and, for that purpose, to build a similar factory in Belfast. Its name was Belfast Silk & Rayon. Sochor Jr. confidently set about producing tablecloths, tea towels, underwear and printed clothing, purchased complex machines for weaving fabrics, half linen and synthetic, and in 1948, he also purchased unused premises at Newtownards Airport east of Belfast, where he established a completely new company, Crepe Weavers.

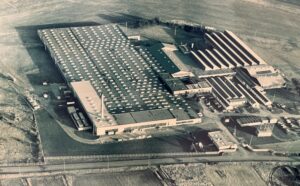

He needed reliable employees and specialists, and found them in other Czech refugees from Nazism and later Communism, especially in my father who had a long-time experience in the field. Thanks to that, we obtained visas to move from Belgium to Northern Ireland and father assisted Mr. Sochor with building the company, originally in two old airport hangars. He was responsible for the quality of products. The financial situation became very difficult because lower sales. The company was not able to afford new machines, bought second hand ones from Lancashire and adapted these with some success to weave the new fabrics. In 1954, my father made a deal with Mr. Sochor and bought the company from him. My brother was already working there, I just happened to finish my degree at Queen’s University Belfast and joined the company, too. I was charged with development on fabrics, looking after the equipment, and even employing and training new personnel. Our company initially produced crepe, a type of rayon cloth, but by the mid-1950s it moved onto a nylon fabric.

Among the many innovations there, it was the first place in the world outside Czechoslovakia to use and develop water jet looms. That was a big thing because they went two or three times the speed of a conventional loom and the noise was much less, so the whole thing became much better for manufacturing and for the personnel. Less noise and almost no dust. Having recognised the potential, the company succeeded to start full scale production using water jet looms in the early 1960s. As the rest of the weaving industry hesitated and remained reluctant in accepting this technology, Crepe Weavers attained a considerable commercial advantage over competition. Therefore, we were able to meet the growing global demand. During the 1970s, Crepe Weavers had 600 looms and was one of the main employers in the town with a workforce of 350 who manufactured half a million square metres of fabric every week.

We also managed to evolve the former factory production site at Comber Road in Newtownards

When my father retired he sold a stake in Crepe Weaves to Courtaulds, a large British textiles company, with whom I managed the company until I bought the entire business back from them in 1983. The company repositioned itself to successfully sell specialist textiles to customers around the world. However, at a certain point, we came under pressure from our overseas competitors and Crepe Weaves ceased operations in 2005. We had a very large production capacity, but we simply could not make progress on the money side. We did not want to leave debt or go into forced liquidation, se we rather shut down the production. Everybody was paid, all our employees got proper redundancies. Only a little factory´s shop remained open. We also managed to evolve the former factory production site at Comber Road in Newtownards of some 25 acres into an industrial estate. We jumped into property development and real estate. I was always looking for a new challenge. I was simply guided by four “I´s”: instruction, innovation, integration and investment. In January 2007, I was appointed honorary consul of the Czech Republic in Northern Ireland. I served until 2021 and tried to promote business and social relationship between the two nations.

Milan Mladek, called „visionary businessman“ who left a deep mark on the business environment of Northern Ireland, passed away on May 4, 2023. His son Mark is a senior lawyer in London.